Blog Posts Tagged 3D Printing

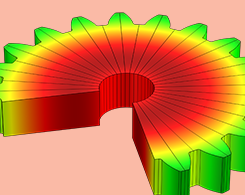

Designing the Sound Absorption of Microlattice Structures

Using numerical simulation, you can design microlattice structures with sound-absorbing properties, and then print them via additive manufacturing without traditional manufacturing constraints.

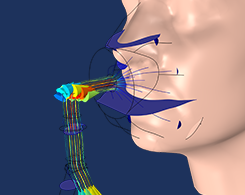

Optimizing an NIV Mask Design with Multiphysics Simulation

NIV masks offer a form of noninvasive monitoring and ventilation for COVID-19 patients, which lessens the need for ventilators and other mechanical respirators.

Introducing the Metal Processing Module

The Metal Processing Module includes 2 interfaces for analyzing diffusive and displacive metallurgical phase transformations: Metal Phase Transformation and Austenite Decomposition.

Comparing Optimization Methods for a Heat Sink Design for 3D Printing

When designing a heat sink, is it better to use parametric or topology optimization? When manufacturing said design, does 3D printing produce the best result, or a conventional method?

How to Activate Material in Simulations of Manufacturing Processes

Do you model manufacturing processes such as welding or additive manufacturing? You can activate or deactivate a material in a material deposition simulation using specialized functionality.

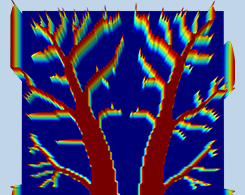

Advancing Additive Manufacturing with Sequential Simulations

In some ways, additive manufacturing is like sewing or weaving. We talk to a professor of additive manufacturing about how sequential simulations can be used to analyze and optimize the process.

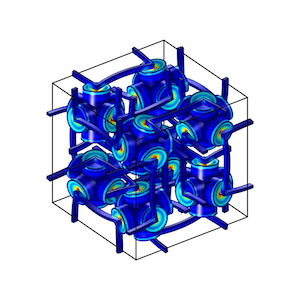

Analyzing a Unique Poroelastic Metamaterial with Simulation

This blog post combines the subjects of 3D printing and metamaterials, featuring a group that used simulation-based research to analyze a unique poroelastic metamaterial.

Analyzing Laser Beam-Matter Interaction in Selective Laser Melting

Selective laser melting is a common and important process in many types of manufacturing. You can model the interaction between the laser beam and matter for a closer look at this process.