Defending Automotive Components Against Corrosive Destruction

Daniel Höche, HZG, Germany; Nils Bösch, Daimler AG, GermanyGalvanic corrosion, which occurs when the surfaces of different adjoining metals begin to degrade, costs the automotive industry billions of dollars annually. The reactions of these different metal combinations is influenced by material properties, surface roughness, and joining techniques in the components.

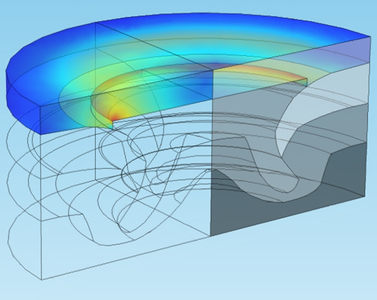

Researchers at Helmholtz-Zeentrum Geesthacht (HZG) and Daimler AG created COMSOL Multiphysics applications to study corrosion in automotive parts found in car paneling. Simulation helped researchers investigate electrochemical reactions on the surface of the rivet, analyze decay in sheet metal, and understand the effects of geometry on the corrosion process. They also modeled delamination of the steel sheet and assessed the growth of a crevice between the metal layers and a cathodic coating as the zinc plating was consumed. With the understanding they gained of the electrochemical behavior, they were able to provide engineers at HZG and Daimler AG with key information to improve corrosion protection in automotive parts.

COMSOL simulation results showing current density on the rivet surface and at the interface between the rivet and adjoined sheet metal.

COMSOL simulation results showing current density on the rivet surface and at the interface between the rivet and adjoined sheet metal.

Download

- Daimler_HZG_CN2015.pdf - 1.35MB