Scopri come la simulazione multifisica viene utilizzata per ricerca e sviluppo

In questa sezione troverete i lavori presentati alle Conferenze mondiali COMSOL. Le presentazioni descrivono ricerche e prodotti innovativi progettati con COMSOL Multiphysics da colleghi di tutto il mondo. I temi delle ricerche presentate abbracciano un'ampia gamma di settori produttivi e aree applicative, in ambito elettrico, meccanico, fluidodinamico e chimico. Lo strumento di Ricerca Rapida vi permetterà di trovare le presentazioni che si riferiscono all'area di vostro interesse.

Visualizza gli articoli presentati alla COMSOL Conference 2020

Among the different uses of primary energy in the industrial and residential sectors, refrigeration and air conditioning systems consume around 17% of the electricity produced worldwide [1], reaching dissipated powers of approximately 2000 TWh [2]. These devices are based on the vapor ... Per saperne di più

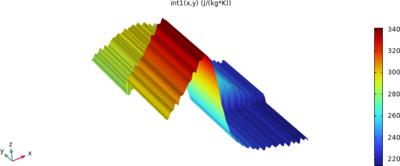

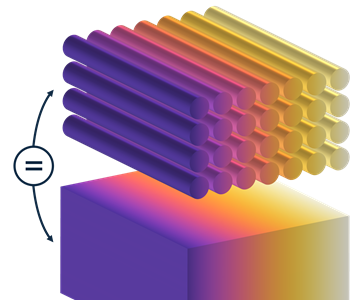

In various industries (nuclear power plants, furnaces, …), heat transfer by radiation can occur between many geometrically ordered tubes. Such configurations are challenging and heavy to solve numerically, because of both the nonlinearities of the radiant exitance, and the fact that ... Per saperne di più

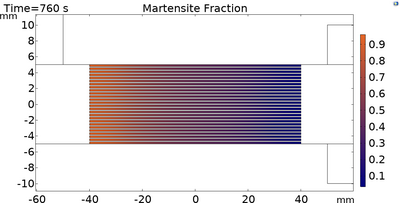

Solid-state magnetic refrigeration near room temperature, based on the magnetocaloric effect (MCE), is being investigated as an environmentally friendly and sustainable alternative to traditional vapor-compression systems (responsible for the 7.8% of greenhouse gas emissions) [1] [2], ... Per saperne di più

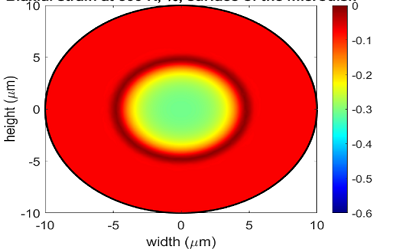

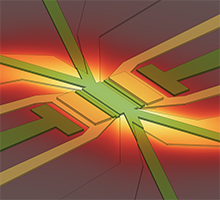

Germanium-tin (Ge₁₋ₓSnₓ) microdisks are emerging as a promising platform for CMOS-compatible group-IV light sources due to their tunable direct bandgap and compatibility with silicon photonics. Their optical and electronic properties are critically influenced by tin concentration, strain ... Per saperne di più

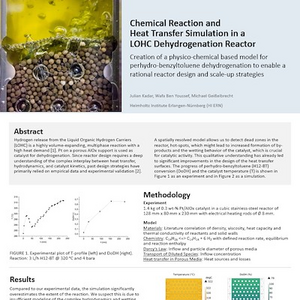

The release of hydrogen from Liquid Organic Hydrogen Carriers (LOHC) is a highly volume-expanding, multiphase reaction with a high heat demand [1]. Platinum on porous alumina support is used as the catalyst for dehydrogenation. Since reactor design requires a deep understanding of the ... Per saperne di più

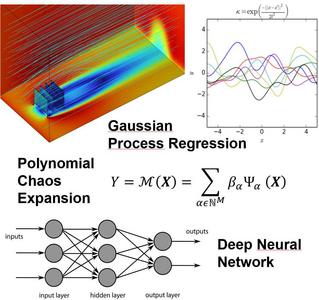

For many years now, numerical simulations allow to calculate and predict processes in many fields such as natural sciences, engineering, and economics. To do this, models of the system under consideration are created and animated using equations based on first principles of physics, e.g. ... Per saperne di più

Quantum heat engines (QHEs) perform a thermodynamic cycle by exchanging heat between a hot and a cold reservoir employing quantum systems as the working medium. Such thermoelectric generators could theoretically reach Curzon-Ahlborn efficiency due to the excellent properties of the ... Per saperne di più

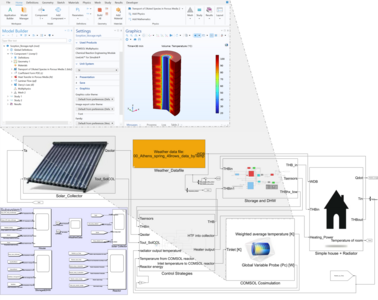

Problem Description Sorption heat storage systems are attracting growing interest due to their high energy density and loss-free heat storage capability, making them a promising solution for storing surplus solar energy in summer for use in winter in residential buildings. However, these ... Per saperne di più

Calibration drift of temperature sensors is a well-known problem which adversely affects process control, particularly at high temperatures. Some new approaches are being developed [1,2], but degradation of resistive sensor elements is hard to prevent. To overcome this, graphene, which ... Per saperne di più

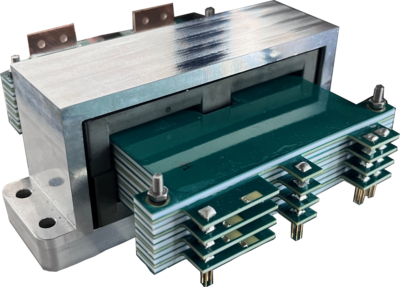

The increasing integration of power electronics into airborne systems drives the need for compact, efficient, and thermally robust solutions that comply with the demanding constraints of the aeronautical environment. In this context, planar transformers offer significant advantages, ... Per saperne di più