Scopri come la simulazione multifisica viene utilizzata per ricerca e sviluppo

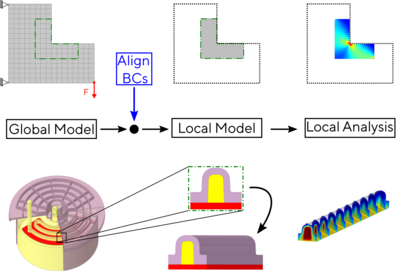

In questa sezione troverete i lavori presentati alle Conferenze mondiali COMSOL. Le presentazioni descrivono ricerche e prodotti innovativi progettati con COMSOL Multiphysics da colleghi di tutto il mondo. I temi delle ricerche presentate abbracciano un'ampia gamma di settori produttivi e aree applicative, in ambito elettrico, meccanico, fluidodinamico e chimico. Lo strumento di Ricerca Rapida vi permetterà di trovare le presentazioni che si riferiscono all'area di vostro interesse.

Visualizza gli articoli presentati alla COMSOL Conference 2020

Introduction: Polymer materials are increasingly used in machine elements such as seals and plain bearings. In particular, PEEK has gained attention for use in wind turbine applications due to its strength and resistance to harsh operating conditions. However, its low thermal ... Per saperne di più

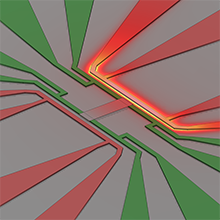

The thermoelectric response of a nanoscale device can be characterized by measuring either the open-circuit thermovoltage or the closed-circuit thermocurrent. While theoretically equivalent through the device's conductance, the thermocurrent measurement offers significant practical ... Per saperne di più

The investigation into the cooling performance of the UniVessel® SU 10 L was conducted through a series of studies utilizing Conjugate Heat Transfer and Heat Transfer in Solids, focusing on design iterations to optimize the cooling channel. The studies aimed to assess temperature ... Per saperne di più

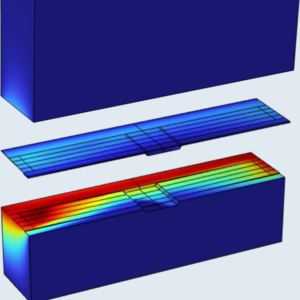

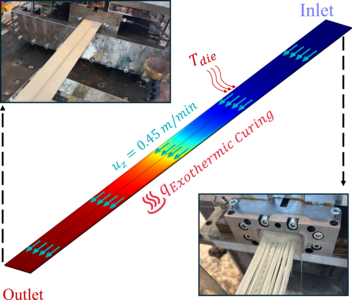

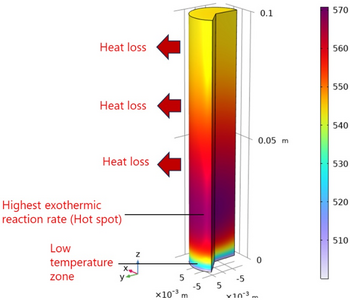

Pultrusion of fibre-reinforced thermoplastic composites presents challenges due to the complexity of achieving uniform curing, particularly when transitioning from traditional thermosetting resins to sustainable, recyclable thermoplastic options. Effective control over parameters like ... Per saperne di più

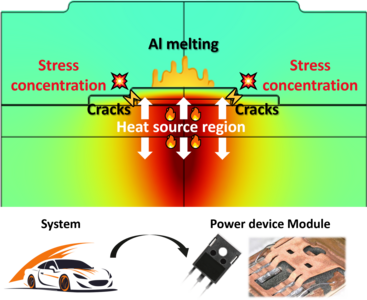

For the first time, a comprehensive coupled 2D electrothermal and elastoplastic transient model of a second-generation planar-gate 4H-SiC vertical MOSFET was developed using COMSOL Multiphysics® to evaluate device behavior under extreme short-circuit conditions (T=300-1500 K). Such ... Per saperne di più

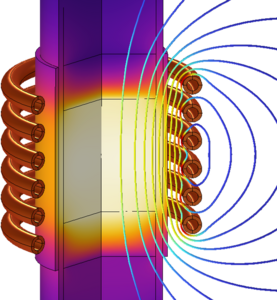

Induction heating (IH) [1] is a good candidate for decarbonization of chemical processes: energy savings, process intensification and production costs reduction [2-5]. Heat can be generated directly into the reactor at the surface in contact with the gas flux passing through a specific ... Per saperne di più

Integrating exothermic and endothermic reactions within a single reactor offers a promising strategy to enhance overall thermal efficiency. However, existing systems often suffer from limited heat transfer performance due to design and heat transfer constraints. To overcome this ... Per saperne di più

In the context of numerical simulation with COMSOL Multiphysics, the implementation of digital twin models for continuous monitoring represents one of the most promising frontiers for improving diagnostics, efficiency and process control in complex systems. In particular, digital twins ... Per saperne di più

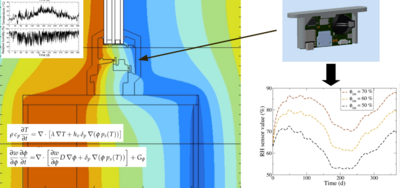

The material wood is frequently used in construction industry for several elements such as window frames. However, as a hygrothermal material, wood is sensitive to moisture induced damage. In this context, the moisture uptake of wood based windows logged with an integrated relative ... Per saperne di più

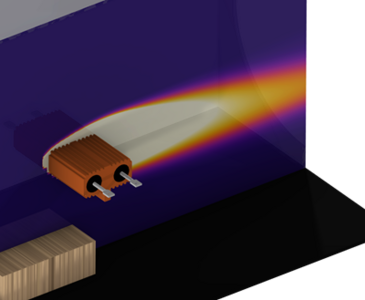

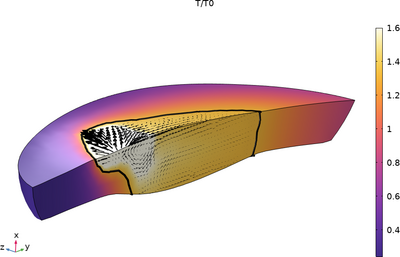

Arc welding is a widely used process in heavy industry for the assembly of metallic components. To ensure high-quality welds, it is essential to understand both the welding process and the complex interactions within the melt pool. Numerical simulation is employed as a predictive tool to ... Per saperne di più