Chemical Vapor Deposition of Titanium Nitride on Machining Tool Inserts

Application ID: 130411

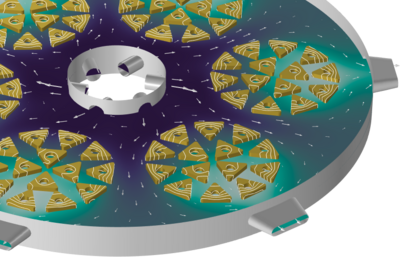

Chemical vapor deposition (CVD) is a process used to grow thin films on substrates. In this CVD example, metal inserts for machining tools are coated with titanium nitride (TiN). The titanium nitride layer improves the wear resistance of the metal inserts by increasing the hardness, reducing friction, and reducing oxidation. Additionally, due to its golden appearance, the coating process is also performed for aesthetic purposes.The CVD reactor in this example operates at low pressures and high temperatures. These operating conditions ensure high diffusion, which is needed for efficient mass transfer onto the substrate surfaces and for homogeneous deposition thicknesses.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® and

- either the Battery Design Module, CFD Module, Chemical Reaction Engineering Module, or Fuel Cell & Electrolyzer Module and

- either the Battery Design Module, Chemical Reaction Engineering Module, Corrosion Module, Electrochemistry Module, Electrodeposition Module, or Fuel Cell & Electrolyzer Module

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Tabella delle Funzionalità and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.