Scopri come la simulazione multifisica viene utilizzata per ricerca e sviluppo

In questa sezione troverete i lavori presentati alle Conferenze mondiali COMSOL. Le presentazioni descrivono ricerche e prodotti innovativi progettati con COMSOL Multiphysics da colleghi di tutto il mondo. I temi delle ricerche presentate abbracciano un'ampia gamma di settori produttivi e aree applicative, in ambito elettrico, meccanico, fluidodinamico e chimico. Lo strumento di Ricerca Rapida vi permetterà di trovare le presentazioni che si riferiscono all'area di vostro interesse.

Visualizza gli articoli presentati alla COMSOL Conference 2020

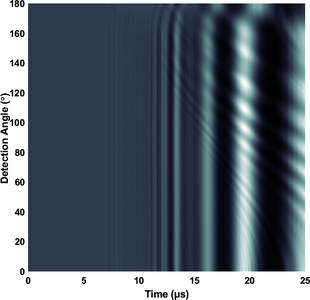

Non-contacting guided wave tomography based on laser ultrasonic waves can be used to inspect structures that are inaccessible to traditional ultrasound methods. Such structures could be, chemically or physically hard to reach, e.g. hot metal structures, metal implants inside tissue or ... Per saperne di più

The interaction of high power laser beam with metallic materials produces a number of interconnected phenomena that represent a serious challenge for numerical modeling, especially for creation of auto-consistent models. Additional difficulty consists in lack of data on materials ... Per saperne di più

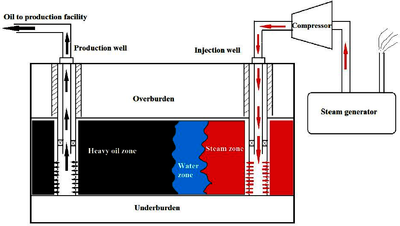

Enhanced oil recovery (EOR) is expanding worldwide to produce more oil from the existing reservoirs to fulfil the demand of the global consumption, which increases on yearly basis. Thermal methods like steam injection and its variations are the most famous methods applied in heavy oil ... Per saperne di più

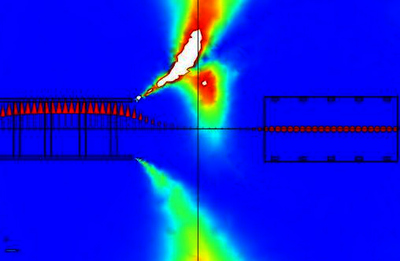

Laser-based powder bed fusion (LPBF) is a promising additive manufacturing technology, where metallic parts are produced in a layer-wise manner. At each step, a rapid-moving laser irradiates and subsequently melts predefined zones of a relatively thin layer of fine spherical metal ... Per saperne di più

Sedimentation is a challenging two-phase problem to model and simulate. Many applications in the industry use sedimentation for separation. For example treatment of wastewater often carried out in settling basins. Different types of the sedimentation process include independent and zone ... Per saperne di più

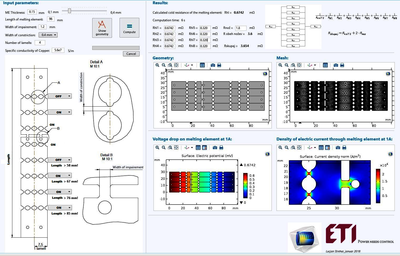

ETI is one of the world’s leading manufacturers of fuses. Different standard sizes, rated voltages, rated currents and tripping characteristics mean more than 750 different types of products. Additionally, our customers sometimes require fuses specifically designed for their needs. Our ... Per saperne di più

Heating of pieces evolving in tunnel furnaces is an argument of high interest in several industrial processes such as thermal treatment of metals, glass production and food industry.Because of pieces move into the furnace, heat flux they receive from fixed heat sources is variable in ... Per saperne di più

Permafrost is defined as soil which remains frozen for at least two consecutive years. In the Swiss Alps, it is a widespread phenomenon with a great impact on the landscape particularly regarding natural hazards. The occurrence of permafrost is not only influenced by meteorological ... Per saperne di più

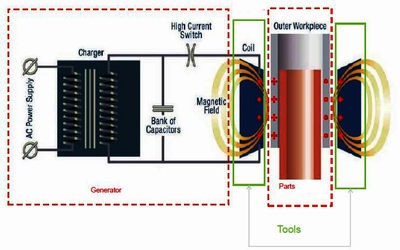

Single turn coils produce AC and transient magnetic fields in pulsed magnetic technologies for which magneto-harmonic and transient magnetic analysis can be primarily performed. We suggest studying one single turn coil example made of a conducting massive coil, an optional conducting ... Per saperne di più

Neutrons are a powerful research tool and provide scientists unprecedented insight into the structure and properties of materials. Experiments with spin-polarized neutrons demand sophisticated neutron optical devices embedded in tailored static magnetic fields. For this study we ... Per saperne di più