Scopri come la simulazione multifisica viene utilizzata per ricerca e sviluppo

In questa sezione troverete i lavori presentati alle Conferenze mondiali COMSOL. Le presentazioni descrivono ricerche e prodotti innovativi progettati con COMSOL Multiphysics da colleghi di tutto il mondo. I temi delle ricerche presentate abbracciano un'ampia gamma di settori produttivi e aree applicative, in ambito elettrico, meccanico, fluidodinamico e chimico. Lo strumento di Ricerca Rapida vi permetterà di trovare le presentazioni che si riferiscono all'area di vostro interesse.

Visualizza gli articoli presentati alla COMSOL Conference 2020

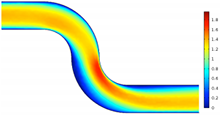

Reynolds Numbers effect: In the first bend, the higher the Reynolds number, the longer the first pair of vorticities stays attached to the wall. In the second bend, the higher Reynolds Numbers, the secondary flow from the first bend dominates. Curvature Radius effect: The smaller the ... Per saperne di più

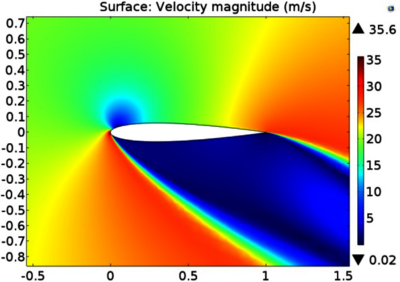

In this work, the CFD Module of COMSOL Multiphysics® software is used to study the efficiency of a Vertical Axis Wind Turbine (VAWT) with independently pivoting airfoils so that wind attack angles of these airfoils are adjustable. The work demonstrates how the efficiency of the VAWT is ... Per saperne di più

Macroscale ultrasonic separation is a new filtration technology, with various applications such as cell clarification, cell therapy, blood-lipid separation, oil-water separation etc. These systems use piezoelectric transducers to create standing waves in fluid-particle mixture. Suspended ... Per saperne di più

Scraped surface heat exchangers (SSHEs) are commonly used in the food, chemical, and pharmaceutical industries for heat transfer, crystallization, and other continuous processes. One of the factor posing difficulties to heat transfer is viscosity. Highly viscous fluids tend to generate ... Per saperne di più

Accurate estimation of rock permeability and porosity play a crucial role in the evaluation of oil and gas reservoirs. This evaluation is, however, challenging in tight formations such as shale due to the slow transition of fluid in such formations with extremely-low permeability. To ... Per saperne di più

The velocity field of a fluid flow in an unbounded domain, R, in which the spin of fluid elements is nonzero only within a bounded subdomain, Ri---namely, the interior of a sphere of radius, a---is simulated by equation-based modeling. A change of independent variable motivated by Kelvin ... Per saperne di più

Airborne particles or aerosols are an unstable system with distributed properties among its individual particulate members. Its fundamental property such as particle size, composition, electrical conductivity, magnetic susceptibility, and morphology could change in response to ... Per saperne di più

Currently, there are approximately 3,400 deepwater wells in the Gulf of Mexico (GoM) having depths greater than 150 meters, and a worldwide undiscovered deepwater reserves estimated to exceed 200 billion barrels and 25% of the total US reserves (BOEM, 2016), while others are in regions ... Per saperne di più

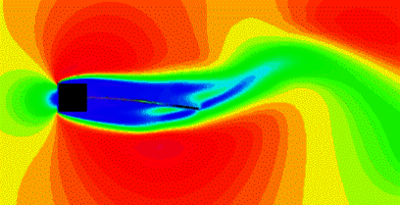

Fluid-structure interaction (FSI) refers to a class of problems in which the motions of fluid and solid are coupled. FSI is of great significance in many applications such as aero-elasticity, biomechanics, and design of various engineering systems. Typically, the multiphysics involved in ... Per saperne di più

Introduction: Ongoing work to improve water and carbon dioxide separation systems to be used on crewed space vehicles combines sub-scale systems testing and multi-physics simulations. Thus, as part of NASA’s Advanced Exploration Systems (AES) program and the Life Support Systems ... Per saperne di più