3D Temperature Dependent Model to Predict Hydration Kinetics of Paddy

Paddy is one of the major cereal crops cultivated in the world. For prolonged storage and usage, parboiling is one of the well-known paddy processing techniques with benefits such as improved yield, sterilization against microorganisms, insect disinfestations and retention of nutrients. Temperature and time play major roles in controlling quality of rice during the soaking process in parboiling. Improper soaking time-temperature conditions results in cracks in the grains and white belly formation. Conventional paddy processing is a time, energy and labour intensive process. Considering this, the main objective of this study was to develop a 3-D CFD model to study the hydration kinetics of paddy at different soaking temperatures to develop a protocol with optimized time-temperature conditions for appropriate soaking of paddy.

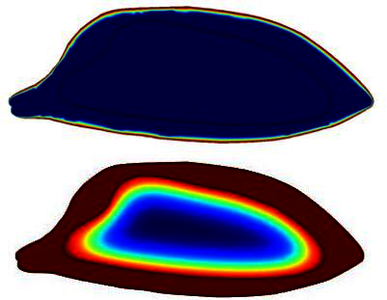

3-D geometry of paddy was developed using grain dimensions assuming known properties of rice and paddy. For this study, ‘Transport of diluted species’ was used, considering the mechanism of Fick’s law of diffusion of water through paddy. A time dependent diffusion analysis was carried out for 8 h. Soaking temperature (30, 40, 50, 60 and 70°C) was also considered in terms of heat transfer aspects of the model; since it has a significant effect on hydration behavior of the paddy. For validation of the model, experiments were carried out in a thermostatic water bath at different temperatures. Paddy samples were assessed for water absorption; and diffusion coefficient of water in paddy was determined. The results were used to understand the effect of temperature on hydration kinetics of paddy.

The developed model was successfully validated against the experimental values, with acceptable error. This proposed model is simple to use and can be employed for other food grains also. It is propounded that the simulated model would help in developing scientific protocols for industrial applications in grain processing also.

Download

- aruva_poster.pdf - 0.64MB

- aruva_abstract.pdf - 0.01MB