Scopri come la simulazione multifisica viene utilizzata per ricerca e sviluppo

In questa sezione troverete i lavori presentati alle Conferenze mondiali COMSOL. Le presentazioni descrivono ricerche e prodotti innovativi progettati con COMSOL Multiphysics da colleghi di tutto il mondo. I temi delle ricerche presentate abbracciano un'ampia gamma di settori produttivi e aree applicative, in ambito elettrico, meccanico, fluidodinamico e chimico. Lo strumento di Ricerca Rapida vi permetterà di trovare le presentazioni che si riferiscono all'area di vostro interesse.

Visualizza gli articoli presentati alla COMSOL Conference 2020

Photocatalysis has received considerable attention in recent years with a huge potential in air purification applications. This work focusses on the semi-passive use of photocatalytic surfaces in streets as an innovative method for removing anthropogenic pollutants (especially volatile ... Per saperne di più

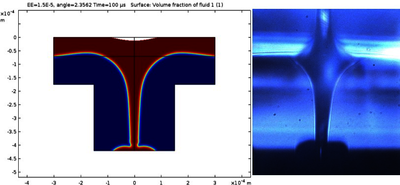

Laser-induced forward transfer (LIFT) is a non-contact direct-write technique that enables the deposition of small volumes of material into user-defined high-resolution patterns with a wide range of structural and functional materials. There are many variations of the LIFT process, each ... Per saperne di più

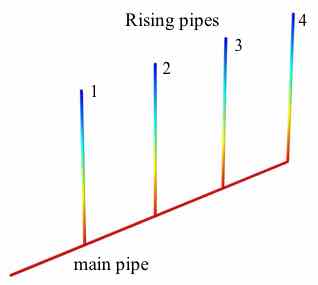

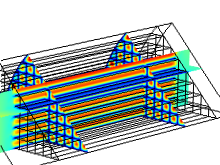

We consider the fluid dynamics problem of homogeneously filling a large tank by multiple inlets fed from a piping system. Suitable pipe geometries must be chosen so that the volume flow is constant for all inlets. In this work, we compare both for a piping system as depicted in fig. 1: A ... Per saperne di più

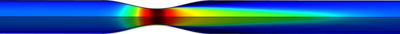

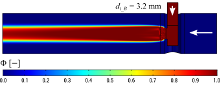

Numerical simulation tools offer the opportunity to ascertain characteristic values, which are difficult to measure. A possible approach for validating simulation models by easy measurable data and gaining the needed values is described in this study of a Venturi tube. The examination of ... Per saperne di più

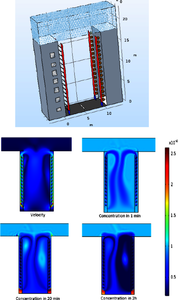

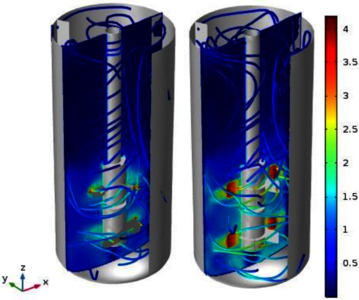

Stirred tank bioreactors are used to simulate a natural biochemical environment for the optimum growth of cells (i.e. algae, microorganisms or tissues) in microbial and cell culture. Bioreactor types range from small (5 L and less) up to 15000 L systems for large-scale industrial ... Per saperne di più

In order to improve hydrogen production in an ethanol reformer it is needed to understand what happens inside it. Also, a simulated model can simulate different work conditions avoiding the necessity of doing tons of experiments. A 3D computational fluid dynamics simulation study of ... Per saperne di più

Two-component adhesives are commonly used for sealing and joining in transport applications for mechanically highly stressed connections. At the Chemnitz University of Technology an innovative system technology for the user-friendly, wireless and energy-efficient processing of two ... Per saperne di più

This assignment deals with the modeling of a pressure controlled current-limiting valve. For this purpose the CAE-Software COMSOL Multiphysics® is used. Current-limiting valves are used as a measure of safety in many hydraulic applications. They are deployed in cases of a high decrease ... Per saperne di più

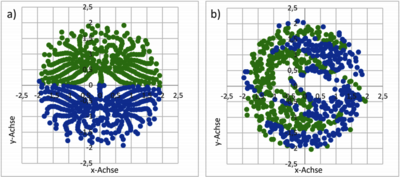

INTRODUCTION This work investigates flow characteristics in pipes and its utilization for a mixing process. The influence of swirl flow on the mixture is of particular interest. There are several studies, which examine the relationship between swirl flow in pipes and heat transfer, such ... Per saperne di più

The paper presents of the application of Kline-Fogleman modified to determine aerodynamic characteristics and flow filed around the exemplary airfoil. This type of airfoil is currently used in models and small unmanned aircraft. Work on the use of this profile in larger aircraft is on ... Per saperne di più