Scopri come la simulazione multifisica viene utilizzata per ricerca e sviluppo

In questa sezione troverete i lavori presentati alle Conferenze mondiali COMSOL. Le presentazioni descrivono ricerche e prodotti innovativi progettati con COMSOL Multiphysics da colleghi di tutto il mondo. I temi delle ricerche presentate abbracciano un'ampia gamma di settori produttivi e aree applicative, in ambito elettrico, meccanico, fluidodinamico e chimico. Lo strumento di Ricerca Rapida vi permetterà di trovare le presentazioni che si riferiscono all'area di vostro interesse.

Visualizza gli articoli presentati alla COMSOL Conference 2020

The reversible storage of hydrogen in metal hydrides represents an attractive technology for hydrogen-based energy systems. In addition to their application as pure hydrogen storage media, metal hydrides can also be used to develop thermochemical hydrogen compressors, which can be ... Per saperne di più

Chemical processes at any level, from laboratory to industrial scale, rely on catalysts due to their ability to reduce energy consumption and increase the yield of the desired products through faster, more effective, and selective reactions. Catalysts such as platinum group metals (PGMs) ... Per saperne di più

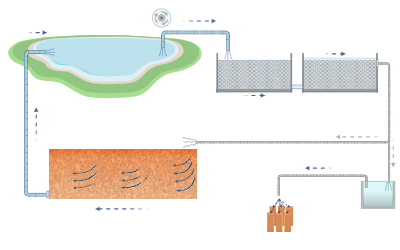

Hypolimnetic withdrawal is a lake restoration technique that targets internal nutrient loading by extracting water from the anoxic hypolimnion, where phosphorus is released from sediments. This method is currently implemented at Lake Kymijärvi in Lahti, Finland, where hypolimnetic water ... Per saperne di più

Accurate, real-time measurement of arterial oxygen partial pressure (PaO₂) is essential for managing respiratory diseases and critical care conditions. Traditional arterial blood sampling for PaO₂ is invasive, painful, and provides intermittent snapshots rather than continuous ... Per saperne di più

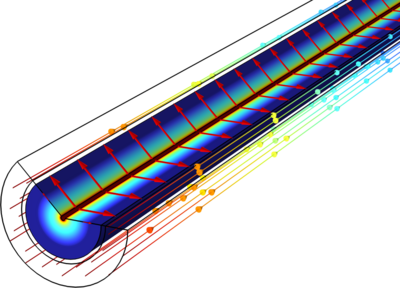

Many industrial processes involving chemical reactions rely on heat addition, which accounts for approximately 50% of all energy consumed in the United States' industrial sector. Examples include metallurgical processes, chemical processing, and heating process fluids. Traditionally, ... Per saperne di più

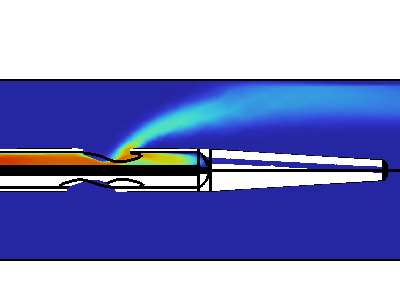

Hemodialysis catheter lumens are routinely locked with heparin solution to reduce the risk of intra-luminal thrombus formation between treatment sessions. The lock volume infused is chosen to be the volume of the lumen, assuming no significant fraction of the heparin dose reaches the ... Per saperne di più

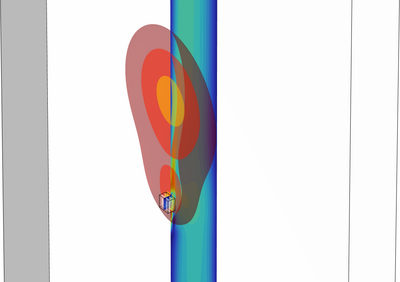

Pleural photodynamic therapy (PDT) represents a promising treatment approach for malignant pleural mesothelioma. However, optimizing treatment efficacy requires accurate prediction of reactive oxygen species ([ROS]rx) distribution, which is challenging due to complex cavity geometries ... Per saperne di più

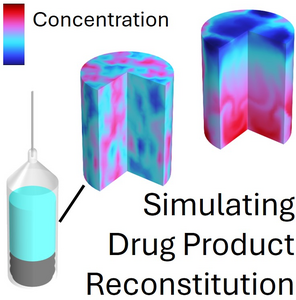

Freeze-dried (lyophilized) drug products offer extended shelf life and improved drug stability within a range of combination products including autoinjectors and pre-filled syringes. A key step in the use of combination products is the reconstitution of the freeze-dried drug product (DP) ... Per saperne di più

This study focuses on the time-dependent behavior of moisture and carbon diffusion within the Fumasep FAA-3-30 membrane, utilized in moisture swing Direct Air Capture (DAC) systems. Understanding the concentration distribution of the species within the membrane over time, water flux and ... Per saperne di più

A Digital Twin Approach for Battery Management Systems for LiFePO4 Batteries Roger Painter 1,5, Ranganathan Parthasarathy 1, Lin Li 1, Irucka Embry 2, Lonnie Sharpe 3 and S. Keith Hargrove 4 1 Department of Civil Engineering, Tennessee State University, Nashville, TN 37209, USA; ... Per saperne di più