Using COMSOL® in a Connected Virtual Factory -Thermal RSM for Rapid Adaptable Packaging Line

A tablet blister cavity is thermally modelled using the Shell interface in COMSOL® and a response surface created to connect to other simulations such as process flow/cost models to form a surrogate model. This virtually represents a pharmaceutical tablet packaging line, that is represented in Siemens HEEDS; to produce information reports on demand. The goal was to avoid tablet product quality defects due to exposure to high temperature during blister packaging.

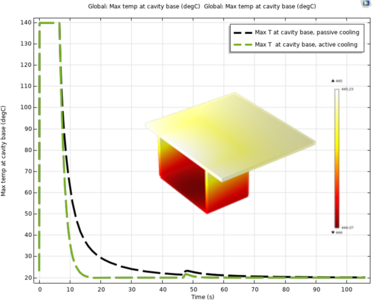

The heat transfer module being employed, whereby several instances of the heat transfer in shells physics interface are used alongside events to control heat impacting the cavity throughout the line. The model provides the temperature of the blister at the critical point of tablet filling and the time to cool to the desired temperature prior to filling/sealing. When utilised as part of the entire surrogate model in the virtual workflow, the results are passed automatically to the operator to enable a control decision to be made, i.e. to action active cooling or extend the cooling wait period prior to filling depending on their priorities at the time.

This was developed as part of one of two dual physical/virtual demonstrators for the Digital Manufacturing Accelerator project, whereby a physical packing line has been commissioned in our Liverpool facility; to enable the industry to reconfigure the system both virtually and physically for a range of different tablet-based products.

Download

- Nute_5211_presentation.pdf - 1.98MB

- Nute_5211_poster.pdf - 3.5MB