Multiphysics Analysis of Laser Cladding Melt Pool

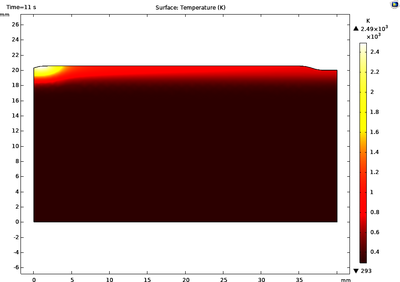

Additive manufacturing is attracting more and more interest. Laser Cladding is one of these additive manufacturing processes. As it is a blown powder process, here a melt pool formation & fusion by moving the laser beam, into which powder is blown and molten & surface tension gradient drives molten material flow thus substrate & clad material gets mixed in the molten state at the interface forming a metallurgical bond. Thereby a layer can be produced track by track and a volume part is built layer by layer. For this analysis a multiphysics based simulation is presented, which has been developed taking into account heat transfer, Conservation equation of energy, momentum and mass of this process are coupled through the temperature variable, melt pool fluid flow and free surface movement are solved to adapt the laser cladding process. Thus the resulting surface geometry of the laser cladding process can be simulated by COMSOL Multiphysics® , which is further validated with the experimental results obtained.