Combustion Resistance of Fine Metal Parts

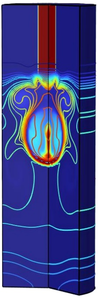

The presence of oxygen in metal installations can influence their flammability, which leads to frequent combustion ignitions. Various studies have been done to characterize this ignition, in order to classify metals according to their degree of flammability, and to minimize the risk of accidents, resulting in the creation of the standardized Promoter Ignition Test PIT G-124 (ASTM/NASA Pyrotechnic Ignition Test). The aim of the present work is to develop a multiphysical model, coupling heat transfers, fluid mechanics and chemical species diffusion, that will represent a numerical flammability test for metals. The model will be based on an Eulerian approach, the so-called Phase-Field method to capture interface deformation, with adaptative mesh refinment, in an axisymmetric configuration to reduce computation time. The thesis work will also include a sensitivity analysis on various (physical/numerical) parameters will be performed to highlight most critical phemona.

Download

- Touzouirt_5281_presentation.pdf - 1.32MB

- Touzouirt_5281_poster.pdf - 0.54MB

- COMSOL_Papier_Samy_V03.pdf - 0.46MB