La Galleria delle Applicazioni raccoglie un'ampia varietà di tutorial e di app dimostrative realizzati con COMSOL Multiphysics in diversi ambiti applicativi, inclusi quelli elettrico, meccanico, fluidico e chimico. E' possibile scaricare i file dei modelli e delle app demo pronti all'uso e le istruzioni step-by-step per costruirli, e utilizzarli come punto di partenza per le proprie simulazioni.

Lo strumento di Ricerca Rapida permette di trovare i modelli che si riferiscono alla propria area di interesse.

Si noti che molti degli esempi qui presentati sono accessibili anche tramite le Librerie delle Applicazioni incorporate nel software COMSOL Multiphysics® e disponibili dal menu File.

Polymer hydrogels consist of a crosslinked network of long-chained polymers that has imbibed a large number of solvent molecules. Such materials are used in many biomedical applications, such as targeted drug delivery, tissue engineering, and stimuli-sensitive actuators. This benchmark ... Per saperne di più

In this example, two model for brittle damage are used to evaluate the fracture of a notched concrete beam subjected to three point bending. The results are compared with experimental data. Per saperne di più

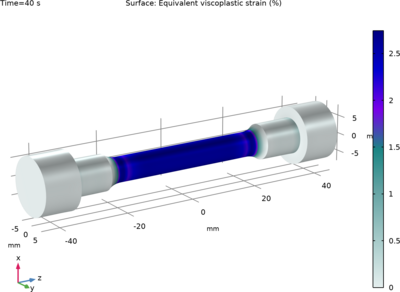

Most metals and alloys undergo viscoplastic deformation at high temperatures. In case of cyclic loading, a constitutive law with both isotropic and kinematic hardening is necessary to describe effects such as ratcheting, cyclic softening/hardening, and stress relaxation. The Lemaitre ... Per saperne di più

This model showcases how to use fibers in thin layers to model thin anisotropic composites embedded in a solid without explicitly drawing either the layer of material or the reinforcing fibers. Here, it is used to model steel cords in tire belts that are used to provide structural ... Per saperne di più

This example demonstrates how to use temperature dependent materials within the Nonlinear Structural Materials Module. A large container holds pressurized hot water. Several pipes are attached to the pressure vessel. Those pipes can rapidly transfer cold water in case of an emergency ... Per saperne di più

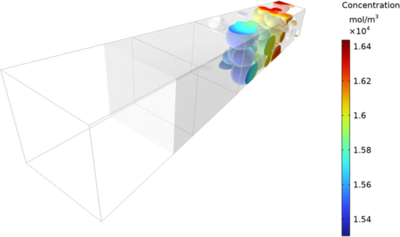

Solid-state batteries (SSB) are a promising technology that could suffer from internal mechanical stresses due to the growth and shrinkage of the electrodes within all-solid components. With this model, the charge-discharge cycling of an SSB is simulated with a focus on the interaction ... Per saperne di più

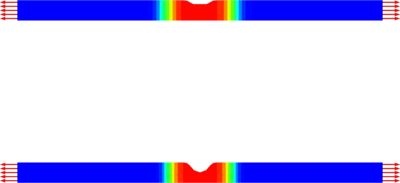

In this tutorial model, different methods for modeling brittle damage are compared in a simple model of a uniaxially loaded bar. The localization of the deformation during fracture is studied using different discretization orders and regularization methods. Per saperne di più

In offshore applications, it is sometimes necessary to quickly seal a pipe as part of the prevention of a blowout. This example shows a simulation, in which a circular pipe is squeezed between two flat stiff indenters until it is almost flat. The model serves as an example of an analysis ... Per saperne di più

A square airbag made of a hyperelastic, compressible neo-Hookean material is inflated using pressurized air. Compressive stresses trigger wrinkling in some regions of the thin airbag. In this example, the wrinkling behavior is modeled using tension field theory, which gives a correct ... Per saperne di più

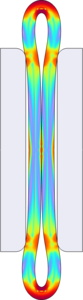

This example simulates the insertion of a snap hook in its groove. Fasteners like this are common in the automotive industry, for example, in the control panel of a car. In this case it is important to know the force that must be applied in order to place the hook in the slot and also ... Per saperne di più