La Galleria delle Applicazioni raccoglie un'ampia varietà di tutorial e di app dimostrative realizzati con COMSOL Multiphysics in diversi ambiti applicativi, inclusi quelli elettrico, meccanico, fluidico e chimico. E' possibile scaricare i file dei modelli e delle app demo pronti all'uso e le istruzioni step-by-step per costruirli, e utilizzarli come punto di partenza per le proprie simulazioni.

Lo strumento di Ricerca Rapida permette di trovare i modelli che si riferiscono alla propria area di interesse.

Si noti che molti degli esempi qui presentati sono accessibili anche tramite le Librerie delle Applicazioni incorporate nel software COMSOL Multiphysics® e disponibili dal menu File.

This example was originally formulated by Albert Witarsa under Professor Bruce Finlayson’s supervision at the University of Washington in Seattle. It was part of a graduate course in which the assignment consisted of evaluating the potential of patents in the field of microfluidics ... Per saperne di più

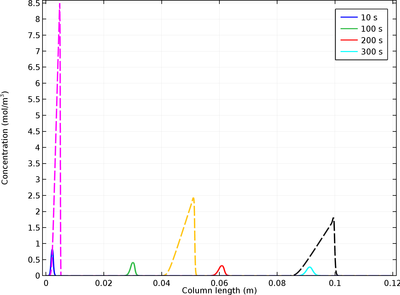

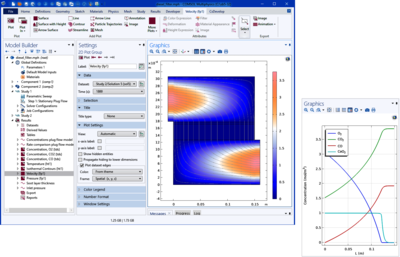

High-performance liquid chromatography (HPLC) is a common method of separating, identifying, and quantifying each chemical compound in a mixture. HPLC is found in the pharmaceutical, biotech, and food industries. The Liquid Chromatography app simulates the separation of two species ... Per saperne di più

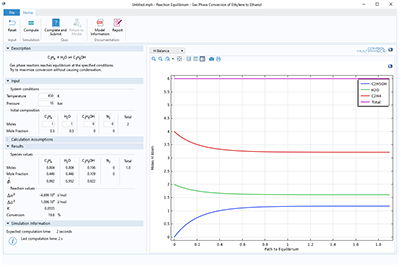

This app demonstrates the following: How an app can be used as a teaching tool An 8 question multiple choice quiz where the answers can be sent to the grader by email This app calculates the equilibrium compositions in gas phase conversion of ethylene to ethanol. It allows you to ... Per saperne di più

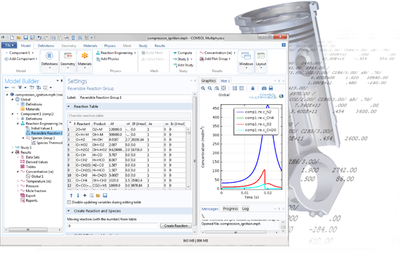

Homogeneous Charge Compression Ignition (HCCI) engines are being considered as an alternative to traditional spark- and compression-ignition engines. As the name implies, a homogeneous fuel/oxidant mixture is auto-ignited by compression with simultaneous combustion occurring throughout ... Per saperne di più

This is a demonstration of how to use the thermodynamics functionality in the COMSOL Multiphysics® software to make flash calculations. A flash calculation is an equilibrium calculation of a system where several species and phases are present at the same time. The system in ... Per saperne di più

This example illustrates the use of the Maxwell-Stefan diffusion model available with the Transport of Concentrated Species interface. It models multicomponent gas-phase diffusion in a Stefan tube in 1D. In this case, it is a liquid mixture of acetone and methanol that evaporates into ... Per saperne di più

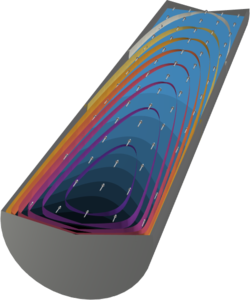

Chemical vapor deposition (CVD) is an important step in the process of manufacturing microchips. One common application is the deposition of silicon on wafers in low pressure reactors to obtain uniform deposition thicknesses. This example models the coupled reaction kinetics, fluid ... Per saperne di più

This application demonstrates how you can access and include external thermodynamic and physical property calculations in your simulation, using the Thermodynamics feature. The example shows how you can easily modify the predefined Plug-flow reactor type in the Reaction Engineering ... Per saperne di più

This model uses the Reacting Flow multiphysics interface to simulate a methane steam reformer. The model accounts for the interactions between the chemical reactions, the transport of species, the fluid flow, and the heat transfer in a porous medium. Per saperne di più

In this tutorial, a filter system for a diesel engine is modeled, including a soot layer development and oxidization. The build-up of the layer is held in check by both catalytic and non-catalytic reactions, where carbon is oxidized to carbon monoxide and carbon dioxide, which in turn ... Per saperne di più