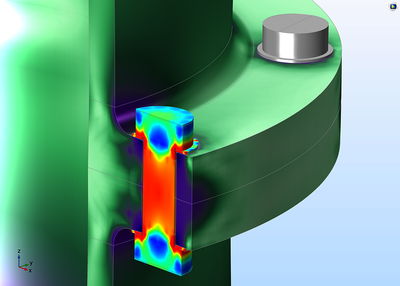

Prestressed Bolts in a Tube Connection

Application ID: 185

A tube connection consisting of a flange with eight prestressed bolts is subjected to a set of loads: an internal pressure, an axial force, and an external bending moment.

Due to two symmetry planes, it is sufficient to only consider one quarter of the full geometry.

The study includes two steps: prestressing the bolts and studying how the stress state in the tube and the bolts varies with the applied external load.

Both the given pretension force and the computed bolt forces of the cut bolts in the symmetry plane are automatically interpreted as if full bolt was present. This simplifies the modeling workflow.

A number of stress classification lines are then created, along which a stress linearization evaluation is performed. Stress linearization is a postprocessing technique where the stresses through a thin section in a solid model are represented by a constant membrane stress field and a linearly varying bending stress field. Membrane, bending, and peak stresses are reported and stress intensities are computed for each such stress classification line.

To learn more about modeling stress linearization, read this blog post: "Introduction to Modeling Stress Linearization in COMSOL Multiphysics®"

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Tabella delle Funzionalità and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.