Understanding the Origin of Uncertainty in Thermometer Calibration

Jonathan PearceNational Physical Laboratory

UK

Thermometers have widespread application and like any measurement device, they must be calibrated. Many do this with the International Temperature Scale of 1990 (ITS-90), which is a platinum resistance thermometer that calibrates using a fixed point cell, which is a container with a well running through its center for insertion of the thermometer. The container has a material of 99.9999% purity. The central well allows a thermometer to be inserted so that the sensing element at its bottom is completely immersed in the fixed point metal. The container is then placed in a furnace to allow controlled melting and solidification of the metal.

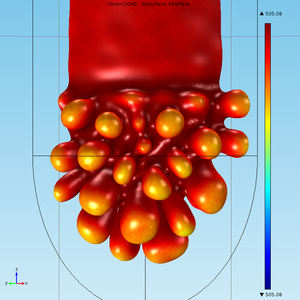

To better understand the microscopic behavior of the phase change processes, researchers at the National Physical Laboratory turned to simulation. They were able to identify specific behavior in a system that is difficult to observe experimentally and yet contributes to the overall uncertainty in a measurement. This showed that the liquid-solid interface is not planar and ripples become apparent that become the cells and begin to protrude outward. The tips of these cells have a significantly lower temperature than their roots. The information gained through simulation can be applied to a thoughtful re-design of the device, ultimately improving measurement precision.

Morphological instability at the liquid-solid interface.

Morphological instability at the liquid-solid interface.

Download

- NPL_CN2013.pdf - 0.52MB