Modeling Optimizes a Piezoelectric Energy Harvester Used in Car Tires

Alexander Frey and Ingo KuehneSiemens Corporate Technology, Munich, Germany

Siemens is a technology company working with electronics and electrical engineering in industry, energy, and healthcare. Researchers at Siemens Corporate Technology are experimenting with an energy harvesting MEMS (Micro Electro-Mechanical System) generator. In collaboration with Continental AG, they are designing a MEMS device for use as a Tire Pressure Monitoring System (TPMS). The movement of the tire transfers mechanical energy to a cantilever beam that, through a piezoelectric material, transfers this to electrical energy.

Without the need for a battery, the TPMS is placed inside the tire rather than on the wheel rim, allowing it to measure more than just pressure. Yet, the positioning of the TPMS means it would have to withstand large centrifugal accelerations, last as long as a tire would, and be light so as to avoid tire imbalance.

Using COMSOL Multiphysics, Siemens was able to simulate the performance of prototypes to investigate it at different parameter values and to optimize the design. They modeled the fluid-structure interaction of the cantilever beam within its surrounding environment, as were able to determine the dampening of its deflection as a function of the surrounding pressure and beam thickness.

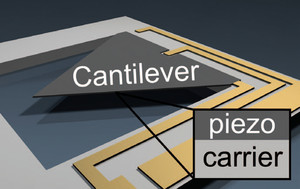

Schematic of the piezoelectric MEMS generator energy harvester. The cantilever is made of two materials, and electrical energy is transferred through the circuit from the cantilever.

Schematic of the piezoelectric MEMS generator energy harvester. The cantilever is made of two materials, and electrical energy is transferred through the circuit from the cantilever.

Download

- Siemens_MS12.pdf - 0.44MB