Aggiornamenti Nonlinear Structural Materials Module

Per gli utenti del Nonlinear Structural Materials Module, la versione 6.4 di COMSOL Multiphysics® introduce modelli di materiali non lineari e la modellazione del danno con phase-field per la dinamica esplicita, insieme a una nuova funzionalità che consente un calcolo più rapido delle deformazioni anelastiche. Proseguite la lettura per ulteriori dettagli su questi aggiornamenti.

Modelli di materiali non lineari per dinamiche esplicite

Per migliorare l'efficienza nell'analisi esplicita nel tempo, sono stati rivisti i modelli di materiali per iperelasticità, plasticità, creep e viscoplasticità. Questi miglioramenti offrono anche significativi aumenti delle prestazioni in altri tipi di studi. I seguenti modelli dimostrano questi miglioramenti:

Nuova interfaccia multifisica Phase-Field Damage, Explicit Dynamics

Per modellare l'evoluzione dei danni e delle cricche nei solidi in condizioni dinamiche, la nuova interfaccia multifisica Phase-Field Damage, Explicit Dynamics combina l'interfaccia Solid Mechanics, Explicit Dynamics con l'interfaccia Phase Field in Solids attraverso un accoppiamento multifisico bidirezionale Phase-Field Damage. Visualizza la nuova interfaccia nel tutorial aggiornato Phase-Field Modeling of Dynamic Crack Branching.

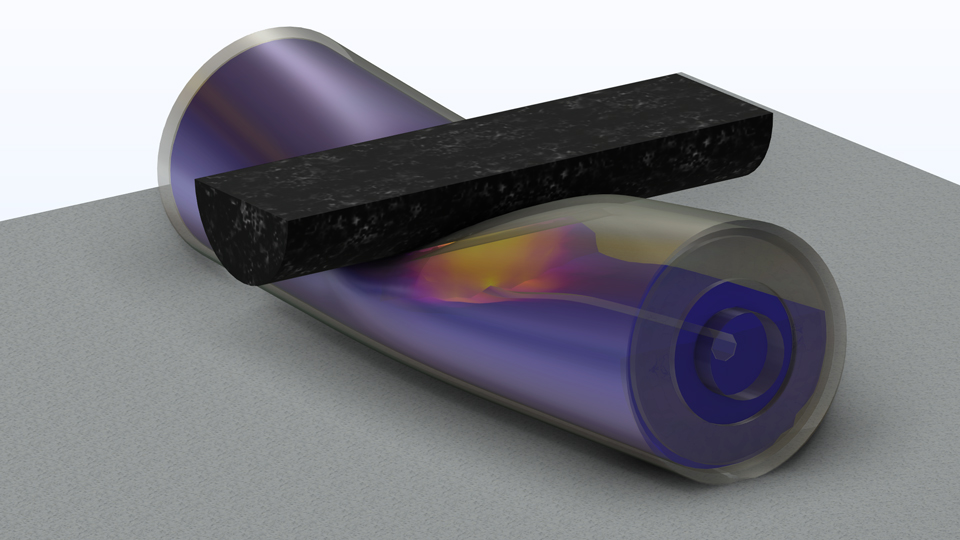

Frattura dinamica di un materiale fragile analizzata utilizzando il modello di danneggiamento AT1 phase-field e la dinamica esplicita.

Decomposizione delle deformazioni secondo Hencky

La nuova opzione di decomposizione delle deformazioni Logarithmic (Hencky) consente un calcolo più rapido delle deformazioni anelastiche rispetto alla tradizionale decomposizione moltiplicativa. Ad esempio, gli algoritmi di plasticità funzionano in modo significativamente più veloce con questo approccio. Il miglioramento delle prestazioni ottenuto selezionando questa opzione è dimostrato nel tutorial aggiornato Compression of an Elastoplastic Pipe, in cui il tempo di calcolo è ridotto del 30%.

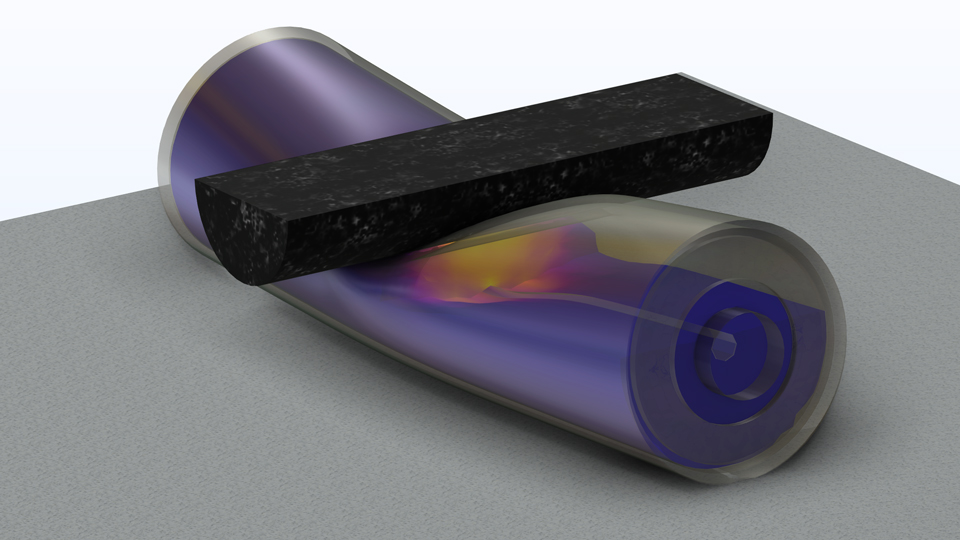

Un tubo metallico viene schiacciato tra due penetratori rigidi fino a renderlo quasi piatto.

Nuovi tutorial

La versione 6.4 di COMSOL Multiphysics® introduce diversi nuovi tutorial nel Nonlinear Structural Materials Module.

Indentation of a Cylindrical Battery Cell

Large-Strain Poroviscoelastic Model of Brain Tissue*

*Richiede il Porous Media Flow Module

Phone Drop Test

Simulazione di un test di caduta di un telefono cellulare. L'urto provoca la propagazione di crepe nel vetro.

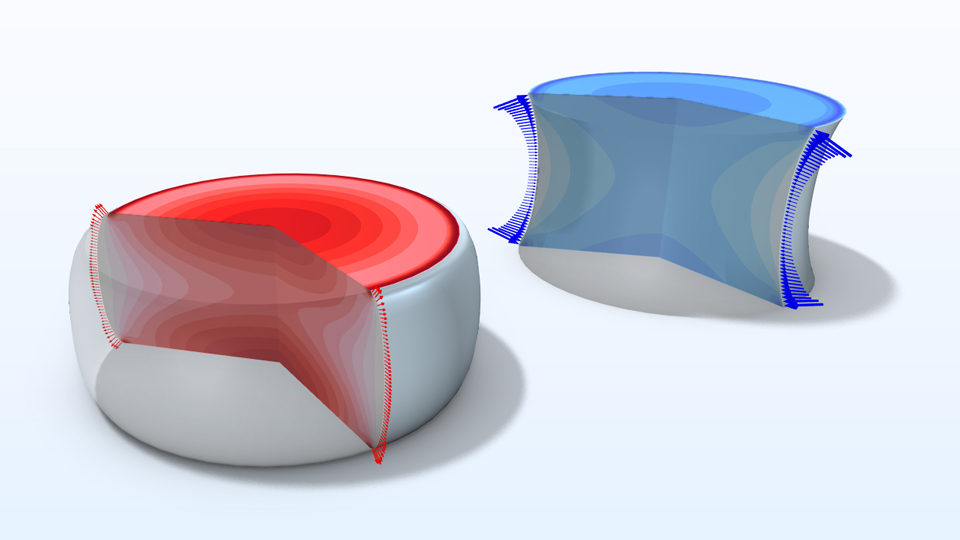

Crimping of a Cable Terminal

Sollecitazione residua di von Mises in un giunto crimpato per cavi dopo la formazione.

Needle Penetration

La modellizzazione dell'inserimento di un ago in materiale simile al tessuto viene effettuata utilizzando un approccio basato sulla zona coesiva per catturare il comportamento della frattura.