Aggiornamenti CFD Module

Per gli utenti del CFD Module, la versione 6.4 di COMSOL Multiphysics® introduce previsioni migliorate della turbolenza transitoria, una modellazione più accurata della turbolenza in prossimità delle pareti e una simulazione ad elevata precisione dei flussi che coinvolgono reazioni chimiche. Proseguite la lettura per ulteriori dettagli su questi aggiornamenti.

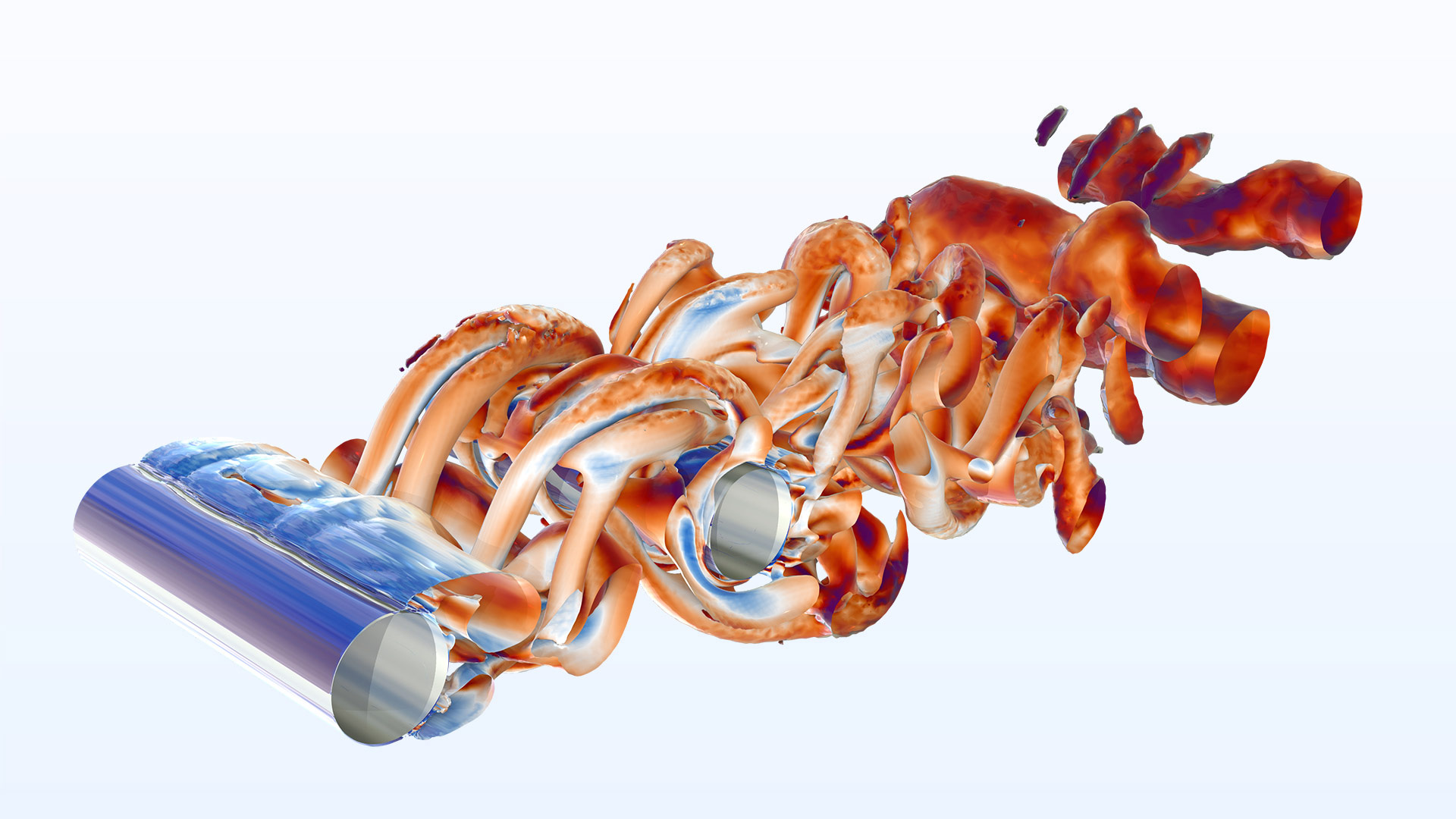

Simulazioni di flussi turbolenti instabili con adattamento di scala

L'interfaccia Turbulent Flow, SST ora supporta la simulazione adattiva alla scala (SAS) incorporando la scala di lunghezza di von Kármán nel modello di turbolenza. Questo approccio risolve una gamma più ampia di scale turbolente e fornisce campi di flusso altamente dettagliati. La SAS può essere applicata in contesti multifisici quali l'interazione fluido-struttura, il flusso reattivo, il flusso non isotermico e il rumore indotto dal flusso, fornendo risultati più accurati e approfonditi.

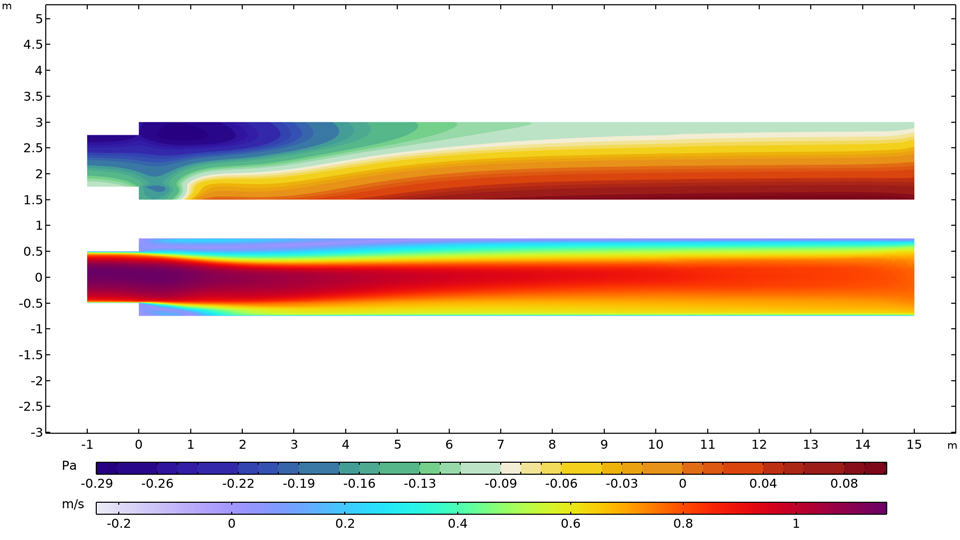

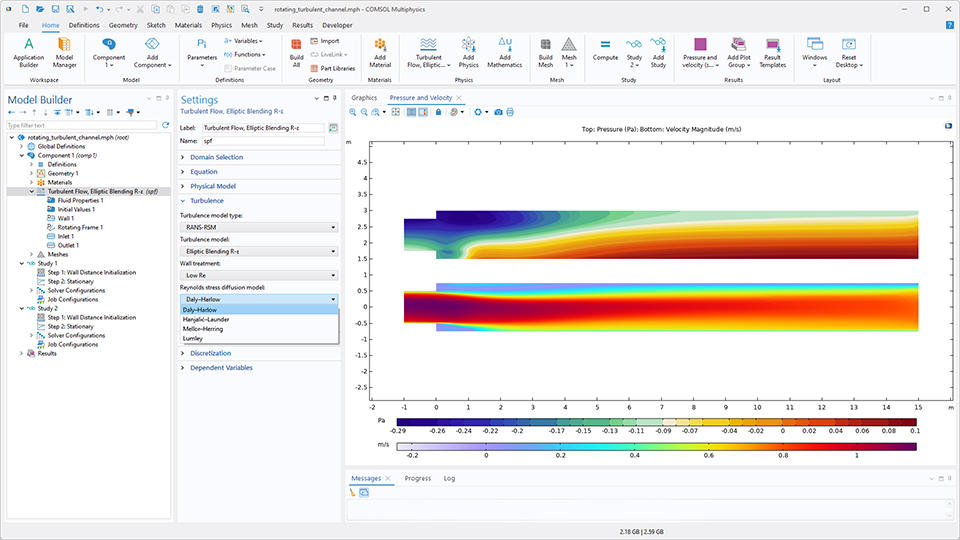

Modello di turbolenza ellittico R-ε con trattamento migliorato vicino alla parete

Combinando le espressioni relative alla correlazione pressione-deformazione e al tasso di dissipazione viscosa della turbolenza nella regione vicino alla parete con quelle relative alla massa, il nuovo modello di turbolenza Turbulent Flow, Elliptic Blending R-ε fornisce risultati accurati per le sollecitazioni di Reynolds vicino alle pareti senza compromettere il comportamento altrove.

LES per flussi reattivi

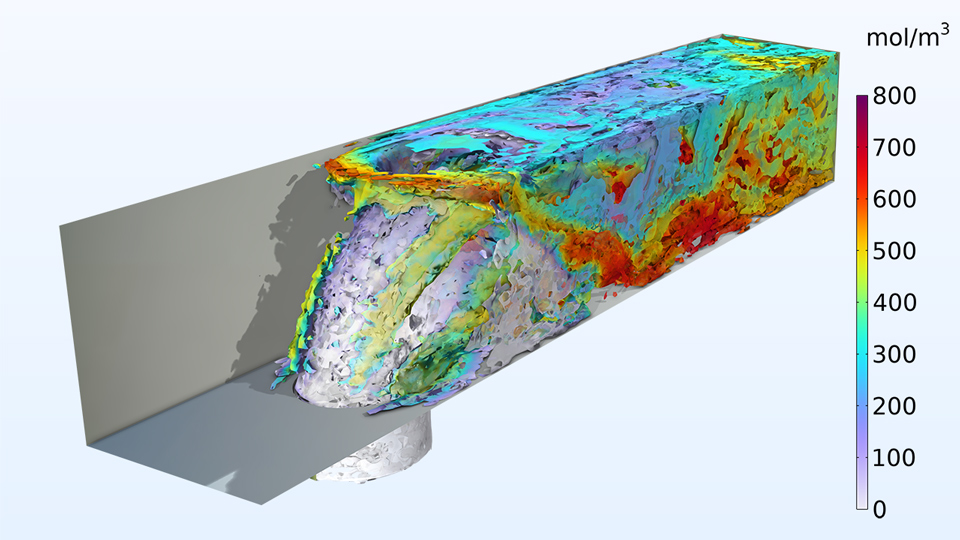

La nuova funzione Reacting Flow con simulazione Large Eddy Simulation (LES) offre una precisione senza precedenti nella modellazione di sistemi reattivi turbolenti. Accoppiando la LES con le interfacce Chemistry, Chemical Species Transport e Heat Transfer in Fluids, è possibile catturare l'interazione dettagliata tra miscelazione, trasferimento di calore e reazioni chimiche in gas e liquidi. L'approccio tiene conto del calore di reazione, della diffusione entalpica e dei flussi di massa, mentre la modellazione LES basata sui residui migliora le previsioni del trasporto di calore e massa. Con l'inclusione delle proprietà dei fluidi e delle sostanze chimiche dipendenti dalla temperatura, questa funzionalità fornisce informazioni altamente realistiche su campi di concentrazione, velocità di reazione e temperatura. Sia che si tratti di studiare reattori catalitici o processi di miscelazione complessi, i modelli di flusso reattivo basati su LES aiutano a rivelare dettagli critici che i modelli di turbolenza tradizionali potrebbero trascurare.

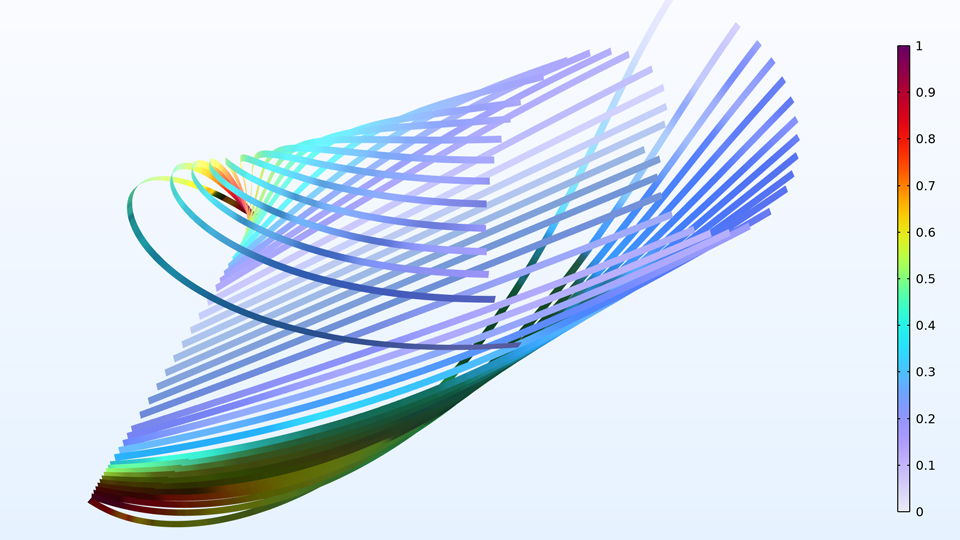

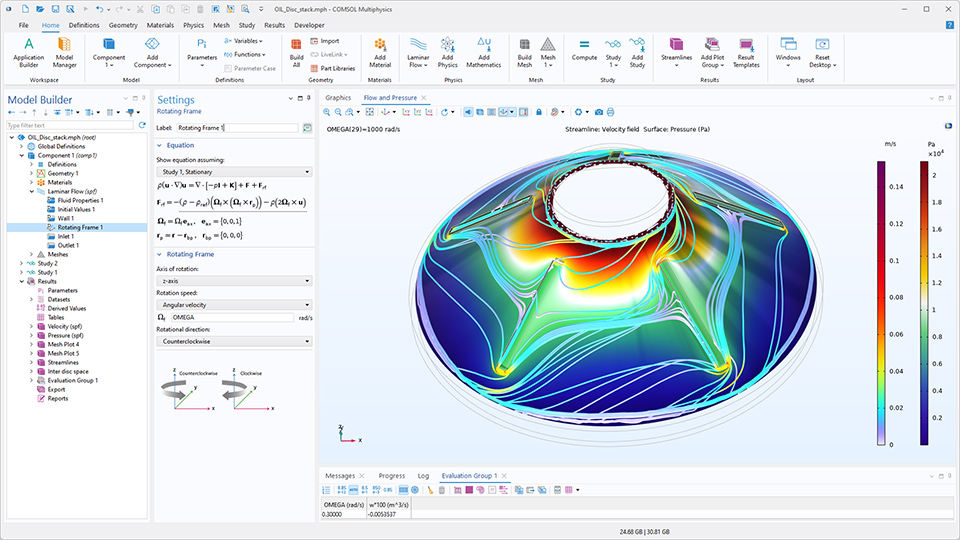

Funzionalità Rotating Frame come alternativa ai domini rotanti

La nuova funzionalità Rotating Frame esprime le equazioni del moto dei fluidi relative a un sistema di riferimento rotante stazionario o dipendente dal tempo, fornendo un'alternativa economica ai domini rotanti senza dover aggiungere equazioni. Offre inoltre opzioni per l'utilizzo di una formulazione a pressione ridotta o l'inclusione dell'approssimazione della pressione idrostatica per la forza centrifuga.

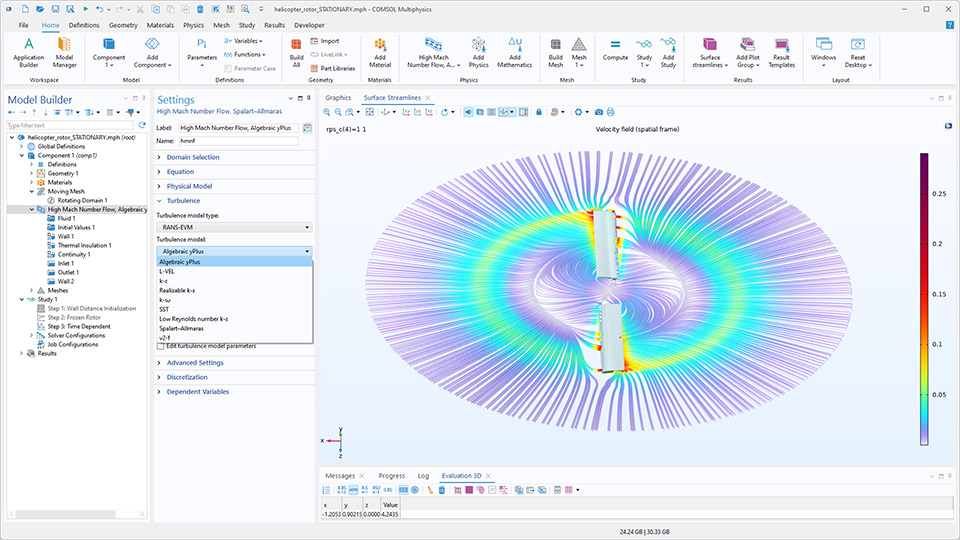

Modelli di turbolenza algebrici per flussi ad alto numero di Mach in macchine rotanti

I modelli di turbolenza L-VEL e Algebraic yPlus sono ora disponibili per flussi ad alto numero di Mach in macchine rotanti. Questi modelli algebrici vengono utilizzati principalmente per generare condizioni iniziali ottimali per modelli di turbolenza più avanzati, migliorando la convergenza e fornendo punti di partenza migliori per simulazioni dipendenti dal tempo, ad esempio nella simulazione di turbomacchine.

Importazione dati di flusso CGNS e aeroacustica

Le simulazioni aeroacustiche e acustiche convettive sono state migliorate con diverse nuove importanti funzionalità. I dati CFD memorizzati nel formato file CGNS possono ora essere importati in COMSOL Multiphysics® utilizzando la nuova funzione CFD Data (CGNS) insieme alla nuova interfaccia Imported Fluid Flow. Questa combinazione garantisce che i dati vengano importati e mappati in modo coerente sulla mesh computazionale. Inoltre, la nuova interfaccia garantisce una perfetta integrazione con gli accoppiamenti multifisici esistenti Background Fluid Flow Coupling e Aeroacoustic Flow Source e con gli studi di mappatura.

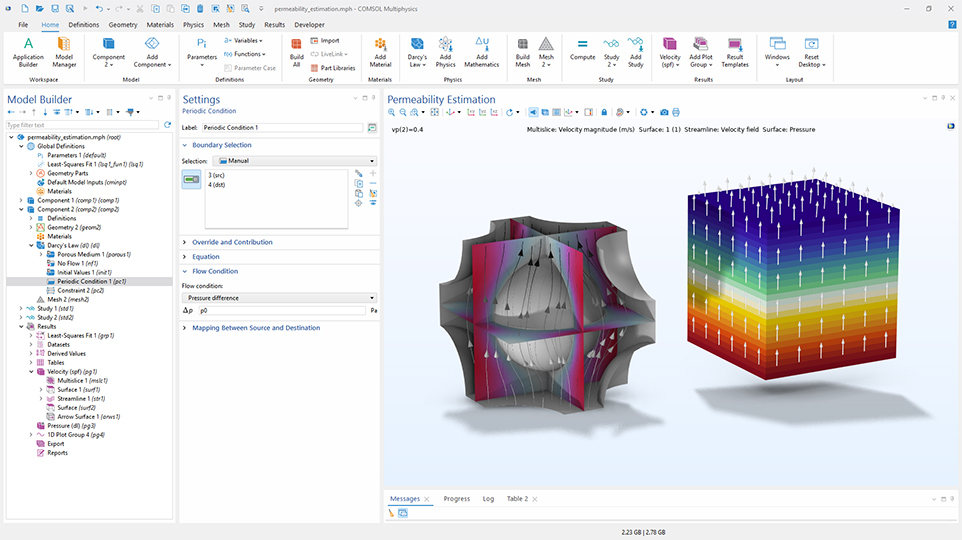

Condizione di periodicità

Una nuova funzione denominata Periodic Condition è stata aggiunta alle interfacce Darcy's Law e Richards' Equation per applicare facilmente la periodicità al flusso tra due o più contorni. Inoltre, è possibile creare una differenza di pressione tra i contorni di origine e destinazione, specificando direttamente il salto di pressione o prescrivendo un flusso di massa. La condizione di periodicità viene solitamente utilizzata per modellare elementi di volume rappresentativi e calcolare proprietà effettive da utilizzare in mezzi porosi omogeneizzati.

Opzione Pressure Jump per l'accoppiamento Free and Porous Media Flow

L'accoppiamento Free and Porous Media Flow Coupling presenta una nuova opzione che consente di includere un salto di pressione attraverso il contorno libero-poroso. Ciò rende possibile modellare, ad esempio, la pressione osmotica su una membrana semipermeabile supportata da un materiale distanziatore poroso o un salto di pressione dovuto alla pressione capillare nel caso di flusso multifase.

Effetto Marangoni determinato dai gradienti di concentrazione

Per i dispositivi e i processi microfluidici, il classico esempio dell'effetto Marangoni determinato dal gradiente di concentrazione è ora incluso nelle funzionalità Free Surface e Fluid–Fluid Interface. Questa funzionalità consente la modellazione di fenomeni determinati dalla tensione superficiale, come le “lacrime del vino”.

Nuovi tutorial

La versione 6.4 di COMSOL Multiphysics® introduce i seguenti nuovi tutorial nel CFD Module.

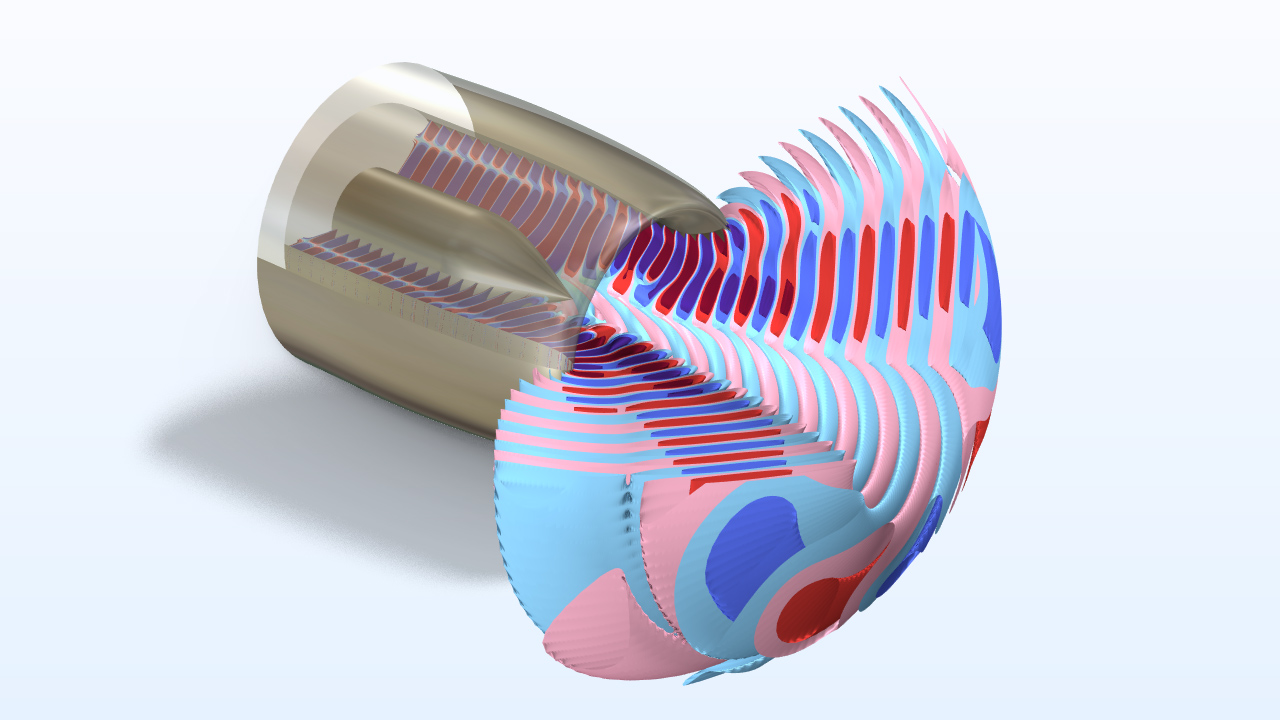

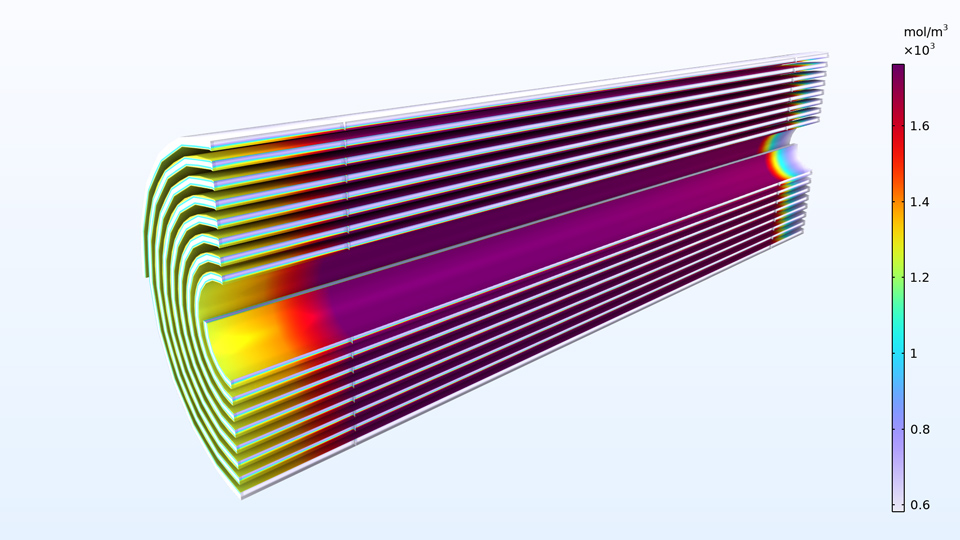

Production of Antibody–Drug Conjugates in a Stirred Tank Reactor*

Un bioreattore a serbatoio con agitatore a quattro pale modellato utilizzando un flusso turbolento reattivo. La concentrazione dell'anticorpo coniugato prodotto nella sintesi è mostrata utilizzando isosuperfici e contorni.

*Richiede il Chemical Reaction Engineering Module

Reverse Osmosis Water Desalination

Axially Rotating Pipe and Swirling Jet Turbulent Flows

Spanwise Rotating Turbulent Channel Flow