Simulation of Reconstitution of Freeze-Dried Drug Product

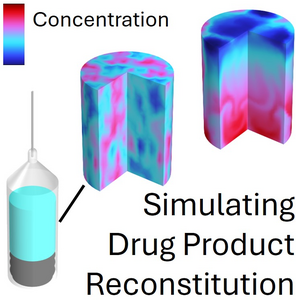

Freeze-dried (lyophilized) drug products offer extended shelf life and improved drug stability within a range of combination products including autoinjectors and pre-filled syringes. A key step in the use of combination products is the reconstitution of the freeze-dried drug product (DP) just prior to injection, where diluent flows into a mixing chamber to dissolve the DP (Figure 1A). Efficient reconstitution is critical to accurate dosing, therapeutic efficacy, patient safety, and ease of use. In this study, we focus on the DP dissolution process, which can be rate-limiting if active mixing is used to homogenize the dissolved DP (Figure 1B). We simulate the dissolution process and its dependence on diluent volume, DP concentration, solution viscosity, and DP particle size distribution.

To simulate the DP dissolution process, we coupled the Laminar Flow, Transport of Diluted Species, and Stabilized Convection-Diffusion Equation (SCDE) interfaces in COMSOL Multiphysics®. The evolution of the DP particle size distribution was modeled by a custom implementation of the Population Balance Equation, which was discretized into N particle size intervals to evolve the particle number density in each interval. A custom MATLAB® script was used to add N instances of the SCDE to the COMSOL model via the LivelinkTM for MATLAB®. The N intervals are coupled through the dissolution term in the Population Balance Equation, which reduces the particle size in undersaturated regions of the solution. As the particles dissolve, solubilized DP molecules are tracked via the Transport of Diluted Species interface. Inputs to the model include the initial DP particle size distribution, the total DP mass, diluent volume and properties.

Snapshots of the 3D distribution of DP particle volume fraction and dissolved DP concentration are shown in Figure 2. The predicted time evolution of DP particle size distribution and DP solution concentration are plotted in Figure 3. As DP particles dissolve, the particle size distribution shifts to smaller diameters, broadens, and the dissolved DP concentration increases. Particle sedimentation results in a concentration gradient in depth (gravity points down). Active mixing is generally then needed to homogenize the DP solution in a short clinical timeframe.

We demonstrate the effect of input parameters on the DP particle size distributions and dissolved DP concentrations in Figure 4. The higher the DP particle concentration, the higher the DP solution concentration and viscosity, and reconstitution time (Figure 4A). Increasing the DP particle size increases slows reconstitution since larger particles take longer to dissolve (Figure 4B). Increasing polydispersity also slows reconstitution since it results in some larger particles, which are dissolution rate-limiting (Figure 4C).

CFD simulations of freeze-dried drug product reconstitution enable visualization of the complex, transient, and coupled flow and dissolution process, a challenging task to achieve experimentally due to the often-self-contained nature of combination products and the short time scales of reconstitution. Simulations also enable alternate designs, operation protocols, formulations, and material and fluid properties to be evaluated quickly, providing insight, and expediting autoinjector and formulation development. Our results provide insights to ensure rapid and effective reconstitution and reliable combination product performance.