Pulsed Electric Field Analysis for Wine Treatment in Static and Continuous-flow Chambers with COMSOL Multiphysics®

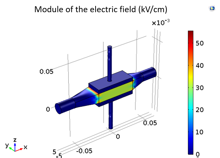

Pulsed Electric Field (PEF) technology is gaining much attention in the food industry, as it offers unique advantages in terms of food safety, preservation of the organoleptic and nutrients properties, and low energetic requirements. Winemaking processes, in particular, can greatly benefit from PEF treatments but require in-depth investigations before moving to the industrialization phase. The scope of the present study is to model PEF treatment of wine in static and continuous-flow chambers in order to optimize the process parameters in relation to the characteristics of the treated product and of the geometry of the chambers. The COMSOL Multiphysics® software was used to analyse distribution values and uniformity of the electric field in different three-dimensional domains, i.e., glass bottle and continuous-flow parallel plate chambers, to ensure the microbial inactivation of the spoilage microorganisms present in wine, i.e., bacteria and yeasts, before and after bottling. Different electrodes configurations for wine bottles as well as two continuous flow parallel plate chamber configurations, with volumetric flow rates of Q=0.72 l/min and Q=3.84 l/min, respectively, have been designed and analysed. For the geometry design in the continuous-flow scenario, the constraints imposed by the UNI EN 10255 standard were considered for the connection of the treatment chamber with the peristaltic pump for flow generation. The AC/DC module of COMSOL Multiphysics® (electrostatic module and steady-state study) was used to solve the Gauss law using the scalar electric potential as a dependent variable and simulate the electric field. The stationary electrostatic module was chosen as the system time constant is less than the duration of the PEF application pulses by several orders of magnitude. For the continuous-flow chamber, the velocity distribution was analysed with COMSOL Multiphysics® by solving the Navier Stokes equations, so that both the desired electric field and treatment time could be controlled. The fluid dynamic study was performed using the k-omega (k-ω) model to solve two transport equations, one for the kinetic energy, k, and one for the turbulence frequency, ω. These equations were added to the system of Navier-Stokes equations, allowing the fluid dynamic analysis in a turbulent motion regime. Various tests have been performed by varying the geometry of the pipe-junction to avoid stagnation of wine and lack of homogeneity in the treatment. The derived computational models allowed us to verify theoretically the feasibility of PEF treatment in the winemaking process. For the case of the glass bottle, as expected, the voltage values required to obtain the desired electric field distribution, with values of the electric field not less than 20 kV/cm within the chamber, are inapplicable with external electrodes for safety and energy consumption reasons. Other configurations are practicable with at least one electrode positioned within the bottle. The designed continuous-flow chambers, instead, are efficient from the point of view of uniformity of the electric field and of the velocity profiles in relation to the treatment time of the wine volume. In the future, PEF-based inactivation solutions are expected to reduce the quantity of added sulfites and improve the quality of wines.

Download

- Casti_PEF.pptx - 0.3MB