La Galleria delle Applicazioni raccoglie un'ampia varietà di tutorial e di app dimostrative realizzati con COMSOL Multiphysics in diversi ambiti applicativi, inclusi quelli elettrico, meccanico, fluidico e chimico. E' possibile scaricare i file dei modelli e delle app demo pronti all'uso e le istruzioni step-by-step per costruirli, e utilizzarli come punto di partenza per le proprie simulazioni.

Lo strumento di Ricerca Rapida permette di trovare i modelli che si riferiscono alla propria area di interesse.

Si noti che molti degli esempi qui presentati sono accessibili anche tramite le Librerie delle Applicazioni incorporate nel software COMSOL Multiphysics® e disponibili dal menu File.

The model includes a compilation of benchmark examples included in the text book: Shape Memory Alloys: Modeling and Engineering Applications. D. Lagoudas Ed. Springer 2008. The model shows the thermomechanical properties of a NiTi alloy sample subjected to uniaxial tension-compression ... Per saperne di più

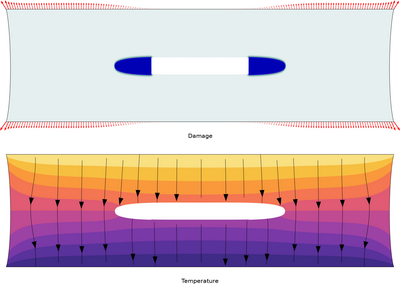

This model demonstrates how to set up a phase field damage multiphysics model to predict crack propagation in thermoelastic solids under large deformations. The crack-driving force depends on the principal stresses, which in turn depend on the temperature distribution in the solid ... Per saperne di più

This model showcases how to use fibers in thin layers to model thin anisotropic composites embedded in a solid without explicitly drawing either the layer of material or the reinforcing fibers. Here, it is used to model steel cords in tire belts that are used to provide structural ... Per saperne di più

The process of filling a water balloon is a vivid example for the interaction of fluid pressure and a nonlinear structural material. This model demonstrates how straightforward a FSI simulation model is set up in COMSOL. Per saperne di più

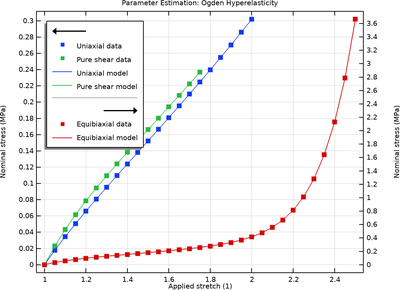

This tutorial model demonstrates how to set up a parameter estimation study for fitting the material parameters of an Ogden hyperelastic model to experimental data. The procedure considers multiple load cases under large deformations, which is often necessary to obtain constitutive ... Per saperne di più

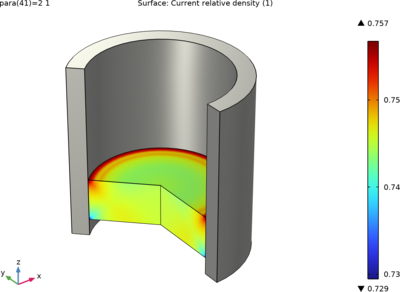

Powder compaction is a popular manufacturing process not only in powder metallurgy, but also in the pharmaceutical industry. The Capped Drucker–Prager model is commonly used for simulating the compaction processes of pharmaceutical powders, where the material properties depend on the ... Per saperne di più

Anisotropic hyperelastic materials are used for modeling collagenous soft tissue in arterial walls. The Arterial Wall Mechanics application describes a section of an artery based on the Holzapfel–Gasser-Ogden hyperelastic material model. In this example the dynamic behavior of the artery ... Per saperne di più

This model shows how you can implement a user defined hyperelastic material, using the strain density energy function. The model used is a general Mooney–Rivlin hyperelastic material model defined by a polynomial. In this example, you will see two material models based on the defined ... Per saperne di più

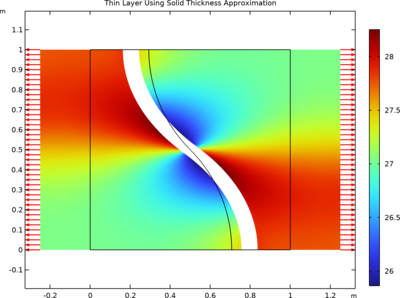

This model demonstrates alternative implementations used for describing a thin layer and the impact of the choice on the continuity of the displacement and stress fields. It is shown how a perfect interface can be obtained by asymptotically changing the material parameters. Per saperne di più

Powder compaction is a key process in powder metallurgy, where it gives the flexibility to produce quality products of complex shapes for sintering. The density of the compact is a key factor to determine the overall quality of the sintered product, as regions with lower density could ... Per saperne di più